Briquetting

plant is the alternate fuel which is derived from agriculture waste or forestry

waste with the aim of protects the environment and our future. Researchers are

finding different ways to change the climate and take care of our environment from

global warming and carbon emission. At that time industrialist finds a way to save

the nature and reuse divested material in a better way with easy and convenient

method which is biomass briquetting

plant Briquetting machine manufacturers play a major role to protect the

environment in efficient way.

Biomass briquetting plant is an efficient way to make briquettes fro

agro waste like groundnut shells, almond shells, bagasse, cotton salk, jute

waste, rice husk, coffee husk, cumin waste etc… or industrial waste which is either

we burnt inefficiently or dumped. So through this plant we can reuse these type

of ravage material and reuse them an efficient way with the help of biomass briquette press which is able

to convert wasted material in to helpful products. Different types of

briquetting machinery available in the market as per your need.

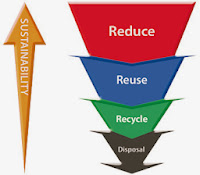

To protect the

environment briquetting machine manufacturer contributes pivotal role in the

world. They are finding a way to protect the environment through their own

discovery biomass briquetting machines which are unbelievable invention in the

industry. The briquette plant manufacturers are making various types of briquetting machines as per

customer’s need and their requirement. With the development of new technology

they are making innovative and accurate briquetting machine which can make

briquette in various shape and design.

The viability of making briquettes as the

demand of it increasing day by day and vise versa the supply the non

conventional sources like gas, lignite and other fossil fuels are limited. Government

also encourages this project and gives a lot of incentives for this future

making plant. The plant is highly growing due to its Eco pleasant features and

reasonable cost. Simple process and easy instalment make this project better

day by day.

In the few years

briquetting plant project gain a lot of credits among the world and In next few

years it will be grown more and more with protecting the mother earth. The

output from this plant biomass briquette is used in various industries as well

as home for cooking and heating.